Technology Platform

SPS sintering principle

Plasma and plasma processing technology

SPS is sintered by spark plasma. Plasma is a state of matter under high temperature or specific excitation. It is the fourth state of matter in addition to solid, liquid and gaseous states. Plasma is an ionized gas, composed of a large number of positive and negative charged particles and neutral particles, and a quasi-neutral gas that exhibits collective behavior.

Plasma is a dissociated high-temperature conductive gas that can provide a state of high reactivity. The plasma temperature is 4000~10999℃, its gaseous molecules and atoms are in a highly activated state, and the ionization degree in the plasma gas is very high. These properties make plasma a very important material preparation and processing technology.

Plasma processing technology has been widely used, such as plasma CVD, low-temperature plasma PBD, and plasma and ion beam etching. Plasma is mostly used in oxide coating and plasma etching, and it also has certain applications in the preparation of high-purity carbide and nitride powders. Another promising application field of plasma is in the sintering of ceramic materials [1].

The methods of producing plasma include heating, electric discharge and light excitation. The plasma generated by the discharge includes direct current discharge, radio frequency discharge and microwave discharge plasma. SPS uses DC discharge plasma.

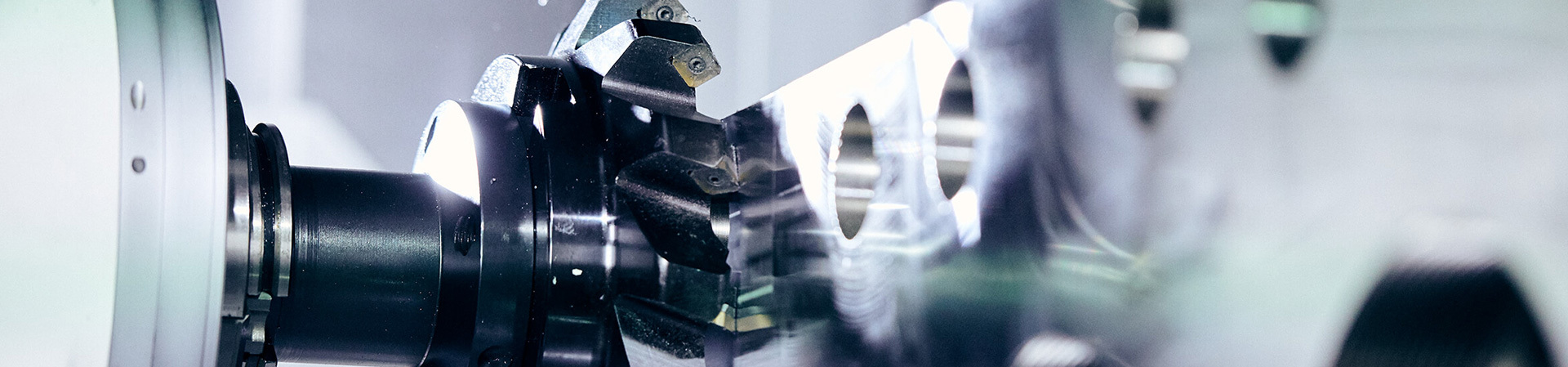

SPS device and basic principle of sintering

The SPS device mainly includes the following parts: axial pressure device; water-cooled punch electrode; vacuum chamber; atmosphere control system (vacuum, argon); DC pulse and cooling water, displacement measurement, temperature measurement, and safety control units .

SPS has similarities with hot pressing (HP), but the heating method is quite different. It is a pressure sintering method that uses on-off DC pulse current to directly energize and sinter. The main function of on-off DC pulse current is to generate discharge plasma, discharge shock pressure, Joule heat and electric field diffusion [11]. During the SPS sintering process, the spark plasma generated instantaneously when the electrode is applied with a direct current pulse current makes each particle in the sintered body uniformly generate Joule heat by itself and activate the surface of the particle. Similar to the self-heating reaction synthesis method (SHS) and microwave sintering method, SPS effectively utilizes the self-heating effect inside the powder for sintering. The SPS sintering process can be regarded as the result of the combined effects of particle discharge, conductive heating and pressure. In addition to heating and pressurizing these two factors that promote sintering, in SPS technology, the effective discharge between particles can generate local high temperatures, which can cause local surface melting and surface material peeling; high-temperature plasma sputtering and discharge shock remove the powder Particle surface impurities (such as surface oxides, etc.) and adsorbed gas. The role of the electric field is to accelerate the diffusion process.